Frp Grating Systems

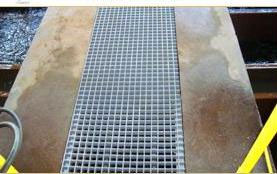

A well designed Composite system is needed for flooring, walkway and decking areas in corrosive environment for superior load bearing and corrosive resistance.

This can be achieved with the use of good quality grade resins with UV inhibitors and other additives with sufficient glass fibre reinforcement.

- Used where mechanical load is very high or support distances are very wide.

- Panels are fabricated to drawing with minimum wastage.

- Performs structurally better than molded grating with a maximum deflection to be limited to span / 200 (the same limit as for steel grating)

- Installation around piping, tanks and other obstacles is much simpler with moulded grating.

- Panels are fabricated to drawing with minimum wastage.

- Performs structurally better than molded grating with a maximum deflection to be limited to span / 200 (the same limit as for steel grating)

- Corrosion and Chemical Resistance

- Slip & Impact Resistance

- Maintenance Free

- Fire Retardant

- High Strength – To – Weight Ratio

- Electrically and Thermally Non Conductive

- Easy Fabrication and Low Installation Cost

- Long Service Life

- Good Load Bearing Capability

- UV Resistant

- Superior Ergonomics & Aesthetic

FRP/GRP PULTRUDED GRATINGS

HPS Pultruded Gratings

HPS Pultruded Gratings are famous for high strength, corrosion resistance in the most difficult environment, long life and safety. These also adhere to the highest international standards. HPS designs ensures that reliable services is possible for several years as they are assembled from interlocking pultruded profiles thus outperforming the traditional materials they replace.

Being lightweight, easy to put together and install, good performance and cost effectiveness makes it a better choice than steel in several major industries.

An entire collection of gratings is offered to satisfy wide-ranging industrial needs and high load requirements for safety at work.

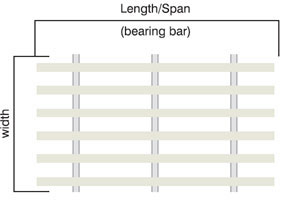

Bearing Bar and Cross Rod Assemblies

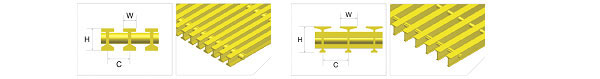

Unlike Moulded Gratings which has equal strength in both directions, HPS Pultruded Grating is stronger in longitudinal direction as it is fabricated from bearing bars, interlocking rods and grove bar assemblies. For that reason HPS Pultruded Grating sizes are specified by width (the cross-rod dimension) X length or span (the bearing bar dimension).

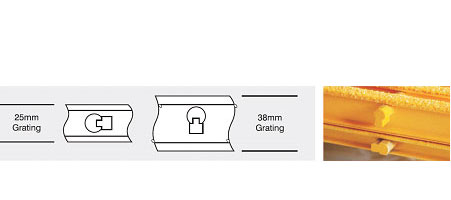

The bearing bars used for HPS Pultruded Gratings are pultruded I bars and T sections and these bars are 25mm (1 inch) and 38mm (1.5 inch) deep and 50mm (2 inches) deep products cross roads are used vertically.

The I bar assemblies are offered in standard size with 40%, 50% & 60% open areas whereas the T bar assemblies have 17%, 33% & 50% open areas as standard. Nomenclature use to describe each industrial grating style refers to its bearing bar style (I or T), its open area and its metric depth.

For example…

I 1560 = I bearing bar : 60% open area : 38mm deep

T 1033 = T bearing bar : 33% open area : 25mm deep

| H- Height | W-Top Width | C-SPacing | Open Area | |

| I-1040 | 25 | 15 | 25 | 40% |

| I-1050 | 25 | 15 | 30 | 50% |

| I-1060 | 25 | 15 | 38 | 60% |

| I-1540 | 38 | 15 | 25 | 40% |

| I-1550 | 38 | 15 | 30 | 50% |

| I-1560 | 38 | 15 | 38 | 60% |

| T-1033 | 25 | 25 | 38 | 33% |

| T-1050 | 25 | 25 | 50.8 | 50% |

| T-1517 | 38 | 25 | 30.5 | 17% |

| T-1533 | 38 | 25 | 38 | 33% |

| T-1550 | 38 | 25 | 50.8 | 50% |

All dimensions in mm

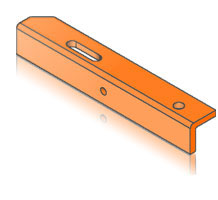

FRP/GRP Strep Treads

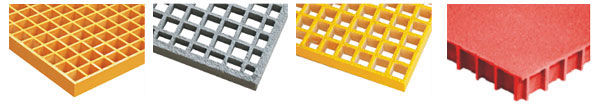

FRP/GRP Moulded Gratings

Molded grating are renowned for their high strength, corrosion resistance in the harshest environments, long life and safety Molded Gratings meet the highest international standards. Produced from carefully selected resin systems, we design to deliver many years of reliable service, outperforming the traditional materials they replace.

Our FRP Gratings are lightweight, easy to fabricate and install. Their acceptance in many major industries has made them the first choice over steel, not only for their performance but cost competitiveness. Comparable with steel at the installed cost stage, their low maintenance and long life means a significantly lower life cycle cost than that of steel.

GRP Moulded Gratings are available with Polyester, vinyl ester or phenolic resin. All kinds of resin are self-extinguishing and UV-stabilized.

Applications

Walkways | Platforms | Trench covers | Staircase | Floorings | Foot Bridges | Swimming pool overflow | Fencing | Elevated car parking | Step Treads | Earth pit covers

Industry

Chemical | Food & Beverage | Marine | Oil & Gas | Power | Industry | Buildings | Constructions | Pharmaceuticals | Pulp & Paper | Recreation | Water & Waste Treatment | Shipping | Transportation | Architectural | Telecommunications

Size

FRP Moulded Grating are made into various mesh patterns and surface suitable for demanding applications.

| Product Code | Height (MM) | Mesh Size (MM) | Rib Thickness (MM) | Open Area (%) | Sheet Size (MM) |

| SM 25 X (38 X 38) | 25 | 38 X 38 | 7-5 | 69 | 3660 X 1220 |

| SM 38 X (38 X 38) | 38 | 38 X 38 | 7-5 | 68 | 3660 X 1220 |

| MM 30 X (20 X 20) | 30 | 20 X 20 (Mini) | 7-5 | 42 | 2003 X 740 |

| SM 50 X (50 X 50) | 50 | 50 X 50 | 8-5 | 71 | 3660 X 1220 |

| RM 25 X (25 X 100) | 25 | 25 X 100 | 6.35 | 68 | 3660 X 1220 |

Surface